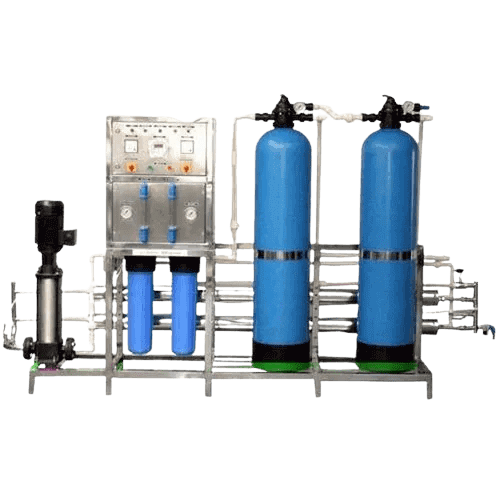

RO Plant for Ice Factory

A reverse osmosis (RO) plant is a water treatment system commonly used in ice factories to purify water for ice production. The RO process involves passing water through a semi-permeable membrane under high pressure, which removes impurities and dissolved solids such as salt and minerals.

RO equipment typically includes several stages of filtration, including a sediment filter, a carbon filter, and a membrane filter. The water first passes through a sedimentation filter to remove larger particles such as sand and dirt. Next, it passes through a carbon filter to remove chlorine and other chemicals. Finally, it passes through a membrane filter, where the reverse osmosis process takes place.

The purified water is then stored in a storage tank and is ready for use in the ice making process. The water that is forced through the membrane, known as wastewater or brine, is usually sent to a sewer or wastewater treatment plant.

RO plants are known for their high efficiency and effectiveness in removing impurities, making them a popular choice for ice factories and other industries that require high quality water for production. In addition, RO systems are relatively low-maintenance and long-lasting.

Overall, the RO plant is an important part of the ice plant’s water treatment system to ensure that the ice produced is safe and of high quality.

Working of RO Ice Factory Plant

Reverse osmosis (RO) ice plants are used to produce high quality ice for a variety of industrial and commercial applications. These plants use a process known as reverse osmosis to remove dissolved impurities and minerals from the water, resulting in pure and clean ice.

The reverse osmosis process begins with water pretreatment. The water first passes through a series of filters to remove large particles or impurities. This is followed by the use of a chemical dosing system that adds a specific chemical to the water to neutralize any remaining impurities or bacteria.

After pretreatment, the water passes through a reverse osmosis membrane. This membrane is made of a semi-permeable material that allows only water molecules to pass through while trapping dissolved impurities and minerals. The purified water is then collected on the other side of the membrane while impurities and minerals are washed away.

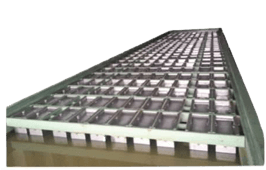

Once the water is cleaned, it passes through a series of cooling coils that cool the water to the required temperature for making ice. The cooled water is then pumped into ice molds and frozen. The resulting ice is then harvested, packaged and stored for later use.

RO ice plants are highly efficient and can produce large quantities of high quality ice in a short time. They are also very easy to operate and maintain, making them a popular choice for industrial and commercial ice production. In addition, the use of reverse osmosis technology ensures that the ice produced is free of any impurities or contaminants, making it safe for consumption.

Overall, the operation of an RO ice plant is a multi-stage process that includes water pre-treatment, reverse osmosis, cooling and ice production. It is a highly efficient and reliable method of producing high quality ice for industrial and commercial use.

RO Plant for Ice Factory

RO Plant for Ice Factory

RO Plant for Ice Factory

The RO Plant Ice Factory is a modern facility that specializes in the production of high quality ice for various industries and applications. Our plant uses reverse osmosis (RO) technology to purify the water before it is frozen into ice, ensuring our ice is free of impurities and contaminants.

We offer a wide range of ice products, including cubed ice, crushed ice and cubed ice. Our ice cubes are ideal for use in beverages, while our crushed ice is ideal for use in seafood displays and cold storage. Our block ice is ideal for use in ice sculpting and carving, as well as for use in industrial cooling applications.

Advantages of RO Plant Ice Factory

Reverse osmosis (RO) ice plants have become increasingly popular in recent years due to their many advantages. These plants use a reverse osmosis process to purify water and create high quality ice. Here are some of the key benefits of using RO equipment in your ice plant:

RO plants use a multi-stage filtration process to remove dirt, bacteria and other contaminants from the water. This ensures that the ice produced is of the highest quality and safe for consumption.

RO plants are highly efficient and can purify large amounts of water quickly. This means ice factories can produce more ice in less time, increasing productivity and reducing costs.

RO units are designed to be low maintenance, with few moving parts and simple operation. This means they are easy to operate and require minimal maintenance, reducing downtime and costs.

RO plants use a membrane filtration system that removes impurities while conserving water. This means ice plants can produce more ice with less water, reducing costs and minimizing environmental impact.

The RO plant not only provides high quality ice but the purified water can be used for other purposes such as drinking water, irrigation or industrial applications.

Overall, using an RO plant in an ice plant offers many advantages in terms of quality, efficiency and cost savings. It is a smart investment for any ice factory that wants to improve its operations and meet the demand for high quality ice.

Advantages of RO Plant Ice Factory

Reverse osmosis (RO) ice plants have become increasingly popular in recent years due to their many advantages. These plants use a reverse osmosis process to purify water and create high quality ice. Here are some of the key benefits of using RO equipment in your ice plant:

RO plants use a multi-stage filtration process to remove dirt, bacteria and other contaminants from the water. This ensures that the ice produced is of the highest quality and safe for consumption.

RO plants are highly efficient and can purify large amounts of water quickly. This means ice factories can produce more ice in less time, increasing productivity and reducing costs.

RO units are designed to be low maintenance, with few moving parts and simple operation. This means they are easy to operate and require minimal maintenance, reducing downtime and costs.

RO plants use a membrane filtration system that removes impurities while conserving water. This means ice plants can produce more ice with less water, reducing costs and minimizing environmental impact.

The RO plant not only provides high quality ice but the purified water can be used for other purposes such as drinking water, irrigation or industrial applications.

Overall, using an RO plant in an ice plant offers many advantages in terms of quality, efficiency and cost savings. It is a smart investment for any ice factory that wants to improve its operations and meet the demand for high quality ice.